The culmination of my most recent loudspeaker construction project is finally here! The JB mk.IV’s are now complete. I spent a good amount of time listening and I’m feeling great about how they turned out. Some digression:

On the enclosure: I would use Red Oak again, for sure. My nervousness for working with hardwood for the first time was totally misplaced. When cut with my circular saw, it was essentially the same as pine or any other softwood. Only with the router did I get burning of the surface and it was fairly easy to simply sand that away. If I did another pair like this, I’d probably pay extra to go to a lumberyard instead of Lowes though, since I suspect that some of the porosity I saw on the inside of my cuts wouldn’t be there with a higher quality of board. You can only expect so much from a big box store.

2-in-1 polyurethane/stain; I would use that again. Wipe-on polyurethane was simply too thin though. That’s good for a final finish only but any sanding is going to take it straight back off again. As my final step I used a triple-thick polyurethane that worked well, although I notice that it did irritate my eyes for about 24 hours afterward, and that’s even with a fan blowing the vapors away from me in the garage. Maybe that stuff has to be used strictly outdoors. The end finish came out quite glossy as you can see in the pictures although it’s not a mirror finish since I did eventually reach the point of no longer caring about how perfect they looked, especially with the flaws already noted in my carpentry. I was too anxious to get to the listening!

On the design: It’s a minimalist design, really. Two driver system with the simplest crossover possible: the -6dB/octave Butterworth filter, which uses only a single capacitor and a single inductor. That’s somewhat of a major feature on these speakers since nearly all popular designs opt for a Linkwitz-Riley filter with the steeper -12dB/octave rolloff that allows the tweeter to be crossed off lower and/or play louder. The values I selected for the components do leave a slight gap: the cap rolls off at 2.65kHz while the inductor rolls off at 2.55kHz.

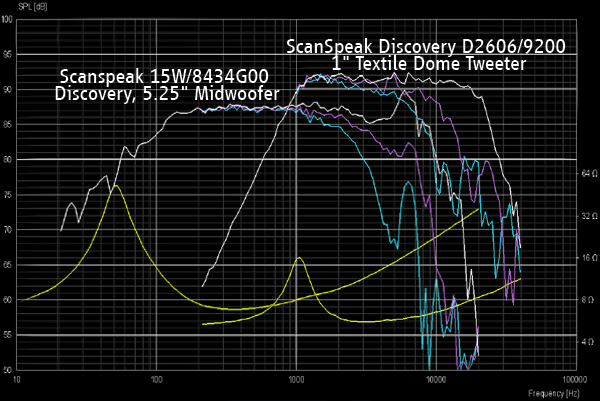

With my mastering and EQing experience, I figured a slight dip at 2.6kHz would actually be pleasing to the ear anyway. The major advantage to the Butterworth filter is a linear phase response to the rolloff region–that is to say there will be no phase cancellation or comb filter effects around the crossover frequency, which all of the other crossover designs suffer from in varying severity. Judging by online reviews of the tweeter and its response curve, I should be able to get away with loud volumes at this crossover point since the resonance frequency of the tweeter is 1.1kHz. Both the tweeter and the woofer had very smooth response curves, so the expected character of the system should be quite neutral. As with my brothers speakers I knew right away I wanted to use an L-pad to compensate for the impedance and sensitivity mismatch between the woofer and the tweeter. The L-pad is a fun way to get a lot of different sonic flavors from a single system as well, since it’s essentially an extra tone control for your stereo system. Never again would I build a speaker without one.

For the crossover components, I did go a bit higher end since there’s only 4 total parts. German copper foil inductor for that precision midrange and a French polypropylene film cap for that snooty, refined treble. I did not even both mounting these to a PCB, instead screwing in a spare piece of wood to clamp down the heavy inductor, and a glob of silicone to secure the cap. Both are soldered directly to the inside lug of the + binding post to eliminate an extra set of connection points. The opposite end of the copper foil inductor was also attached directly to the woofer binding post, so it actually has no extra internal wiring on the + connection. For the rest of the wires I used 14 AWG solid copper wire that I also employ as the main bus wire on my railroad. It’s the same type of wire an electrician would use to wire light switches and outlets in a house, so very heavy duty. Totally overkill considering the stranded speaker wire which will probably be connecting these to any amp. It is somewhat difficult to work with though, since it’s stiff and fights against every bend. I’m 50/50 on whether I’d use it in another design.

Philosophically, these units are quite different than the large speakers I built back in high school that are serving in my living room: those are 3-way with a dome mid, powerful low-reachingwoofer, and a complex computer-designed crossover that has like 40 elements in it. Since there are so many possible choices to make with speaker design it’s almost stupid to do the same thing twice but what can I say, I loved the tweeters from my brother’s green speakers so much that I had to use the same model again on these units since I missed their sound. Every speaker I’ve ever done has used cloth dome tweeters since I prefer their gentle timbre over a metal dome or a horn.

On the sound: I already knew that these tweeters were fantastic so they have been a joy to have back in my life again, so the ScanSpeak midwoofer is really the new player of intrigue for me here. Prior to building my brothers green speakers I had always wondered about the revered ScanSpeak brand and having been blown away by how good their tweets sounded I resolved to use a woofer of theirs as well on my own design.

Initially my impression was neutral. The effect that a quality midwoofer has on the overall sound is more subtle, compared to the airy, delicate treble of fine tweeters. Woofers typically do need a break-in period to loosen up and these seem like they needed that more than other drivers I have known… In my initial listening I did listen to “Spotlight” by SPC ECO and while experimenting with the tone controls on my Kenwood, I flipped on the 800Hz presence boost and immediately exclaimed “Oooh! Oh yeah!” after just a few moments of taking in the sound. Since the midwoofer is taking charge of everything from 2.55kHz and below, that’s definitely all his doing. I’ll need to spend some time breaking these in first, then listening to familiar material to give a true appraisal….

As for the bass, it does not extend very low, but that was an intentional feature of the overall design. These speakers are intended to be paired with a subwoofer, not yet built. Knowing that, I purposely chose a midwoofer that had a high roll off and a good high end. Ideally I would have preferred a closed box but without making it a three-way design I could not find a driver that satisfied me. Everything that would go low enough in a closed box had a poor top-end response, either not reaching far enough or having too rough of a curve for my taste. Perhaps in the future I may experiment with drivers that do have coarse resonances and choppy curves. Like I did mention before, some dips in the response curve can sound pleasing in the right spots.

I have superimposed the response/impedance plots of both drivers here; the plot is remarkably smooth for both drivers and with a 1.5×4″ port, an F3 of 80Hz is achievable with this woofer according to the Madisound website. Final enclosure volume is 4.5 liters or 0.16 cubic feet which is fairly small. The intended volume was 4 liters for the port design, but it’s good to go slightly over for internal bracing, components and stuffing; factoring those variables in, we’re probably beneath 4 liters again, but I have read that stuffing makes a box “look” bigger to a woofer. Another point of compromise was the ratio of sizes between front/top/sides. Ideally I would use 1.618, the fabled golden ratio. However the size of the driver faceplates dictated that wasn’t going to be possible, so I ended up with 1.3 and 1.9 instead.

One other thing I did was to router off a smooth rounded edge on all sides of the front to reduce diffraction of the high end. The tweeter faceplace comes right up to the edge of the front panel though, so a harsh edge was unavoidable there. Curiously, I like the way the treble sounds when standing slightly above the axis of the tweeter so maybe a certain amount of diffraction is good sometimes? Or that could just be the overall directional response of both drivers that I’m hearing or something else entirely, who knows.

More for my own later reference down the line than anything else, here is a breakdown of the parts:

10uF Solen PB10 mfd Metalized Polypropylene film fast cap

0.50mH Goertz CF.5 (16AWG) copper foil inductor

ScanSpeak discovery D2606/9200 1″ textile dome tweeter

ScanSpeak discovery 15W/8434G00 5.25″ midwoofer

Yung 100W 8ohm L-pad

Goldwood 1.5×4″ flared port

Lowes Red Oak panel x2, 7.25″ wide

Generic gold binding posts

And some further reports as my listening extends into the weeks:

Moving these speakers from my Kenwood receiver over to my Marantz PM750DC yielded a major difference in the sound. Maybe it’s a combination of the room and the speaker placement but they have a new life to them near the railroad now.

Moving these speakers from my Kenwood receiver over to my Marantz PM750DC yielded a major difference in the sound. Maybe it’s a combination of the room and the speaker placement but they have a new life to them near the railroad now.

Basslines on Donny Hathaway’s rendition of “What’s Going On” come out clear and defined from my Marantz 6100 turntable. I underestimated the capabilities of these midwoofers on their low end. Happily thus far I haven’t heard a tune that exposes any bloated notes on basslines. That’s always a pet peeve for me. These speakers will really shine with a sub, afterall that’s how they are meant to be paired. But until that’s built I can be content with what’s here.

Basslines on Donny Hathaway’s rendition of “What’s Going On” come out clear and defined from my Marantz 6100 turntable. I underestimated the capabilities of these midwoofers on their low end. Happily thus far I haven’t heard a tune that exposes any bloated notes on basslines. That’s always a pet peeve for me. These speakers will really shine with a sub, afterall that’s how they are meant to be paired. But until that’s built I can be content with what’s here.

A whole new amount of depth and life appeared on Royksopp’s “Senior” album, one I have not listened to on a great set of speakers intently.

A whole new amount of depth and life appeared on Royksopp’s “Senior” album, one I have not listened to on a great set of speakers intently.

Found a few new details in familiar recordings: you can hear the snare rattle as the toms are played at the beginning of Steve Miller Band’s “Fly Like an Eagle”. And there is some kind of percussion instrument I never noticed before despite listening to Seal’s “Dreaming in Metaphors” hundreds of times–a song I used to be all about in high school.

Found a few new details in familiar recordings: you can hear the snare rattle as the toms are played at the beginning of Steve Miller Band’s “Fly Like an Eagle”. And there is some kind of percussion instrument I never noticed before despite listening to Seal’s “Dreaming in Metaphors” hundreds of times–a song I used to be all about in high school.

Something totally unexpected: I often listen with an extra compressor plugin “juicing up” anything being played over the PC, but who knew–with these new speakers I find myself turning the compressor off more and more, just listening to the original audio exactly as it was. Compressors can often bring out extra details but jeez, these speakers are exposing how a wide dynamic range actually sounds better than a totally squashed signal that has all information crunched into a narrow volume range. That’s a beautiful realization I did not anticipate.

Something totally unexpected: I often listen with an extra compressor plugin “juicing up” anything being played over the PC, but who knew–with these new speakers I find myself turning the compressor off more and more, just listening to the original audio exactly as it was. Compressors can often bring out extra details but jeez, these speakers are exposing how a wide dynamic range actually sounds better than a totally squashed signal that has all information crunched into a narrow volume range. That’s a beautiful realization I did not anticipate.

Getting a new pair of speakers sure is a great excuse to go back and listen to familiar music you may have listened to over and over at one point in your life…. which takes it all back to what this whole pursuit is really about

Getting a new pair of speakers sure is a great excuse to go back and listen to familiar music you may have listened to over and over at one point in your life…. which takes it all back to what this whole pursuit is really about